Polisher

A precious metal polisher is a specialist metalsmith who has perfected the technique of putting a finish onto the surface of metal using a variety of polishing, finishing, buffing and plating techniques.

Polishing is a finishing technique used on metal. It is the process of refining a metal surface using abrasive compounds applied by hand or by a polishing wheel which runs at high speed. Various finishes may be obtained with a variety of abrasive compounds applied to the polishing wheel. Rouge is known as the compound that imparts the brightest finish.

“To make a mirror you need glass coated with a highly polished metal such as silver, gold or chrome.”

What personal attributes are useful for a polisher?

To be a polisher you need to be:

- Interested in working with metals

- Possess good manual dexterity

- Patient

- Meticulous

- Willing to get dirty, dusty and not mind a noisy environment

- Safety conscious as you will be working with dangerous machinery

- Trustworthy – you will be working with someone else’s piece

- A good listener – you will be finishing someone else’s pieces to their specification and should understand what they are looking for

It takes practice and years of experience to learn to polish and finish precious metal to a high standard. Exceptional polishers are patient and have developed the skills to understand how objects are made and finished. It takes skill to polish an item without changing its unique character. Every designer or silversmith have their own way of finishing a piece and you need to take the time to understand their work.

What will my working life be like as a polisher?

Polishers work in a workshop, normally from a work bench or polishing motor. You can either be employed to work for a company or self-employed. If you work for a company you are part of a bigger team, earn a wage and have standard hours from Monday to Friday. If you own your own business, your workshop can be at home or shared with other craftspeople. Good business, finance, marketing and interpersonal skills are necessary to run your own business.

Within your work you must be able to adhere to industry health and safety requirements including the Personal Protective Equipment required when polishing; understand the safe storage, handling and disposal of harmful materials used in the workshop including the risks involved in the use of polishing; know how to safely operate and maintain your machines and tools and learn how to adequately process your materials.

You will find it useful to maintain a working knowledge of precious and semi-precious stones, their hardness and what solutions they can and cannot be immersed into; the adequate processing of precious metals their alloys and solders; an understanding of various lubricants and abrasives; and know about antique and modern construction techniques.

As a polisher you will use skills and techniques including preparing and finishing items in accordance with drawn, verbal or written Instructions, executing to the instructions given; applying suitable polishing skills and techniques

using the material supplied; the preparation of surfaces; application of the correct tools to suit the material and condition of articles; knowledge of cleansing techniques; plating including Rhodium plating; buffing; and have the ability to match polished finishes to existing surfaces.

You can expect to work with gold, silver, platinum and solders. And you will learn how to use tools including Personal Protective Equipment; polishing threads and tapes; burnishers; Water of Ayr stones; buff sticks; loupes; brushes; mops and polishing compounds. You should receive training in all of these as required.

A day in the life of a polisher - Carys Hindry

Meeting with a customer to pick up or drop off a job.

Meeting with a customer to pick up or drop off a job.

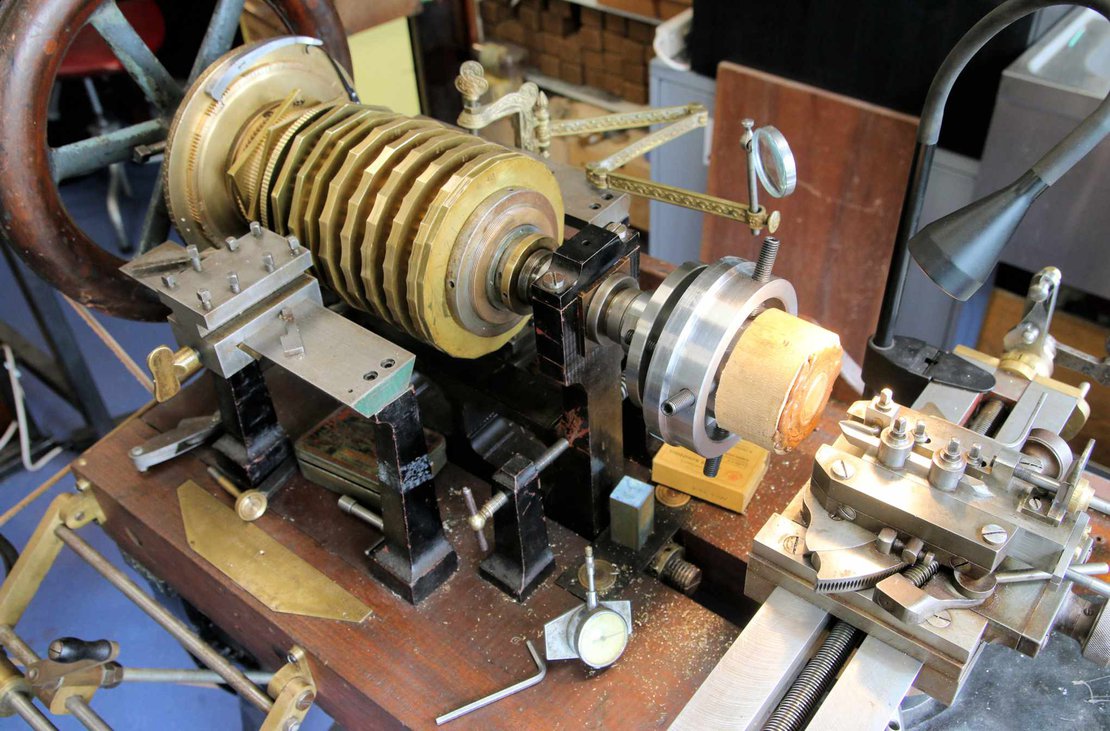

At the polishing station.

At the polishing station.

At the polishing station.

At the polishing station.

Pen plating for intricate sections.

Pen plating for intricate sections.

Polishing the inside of a ring.

Polishing the inside of a ring.

The final stage of polishing, the finishing mop.

The final stage of polishing, the finishing mop.

Training or qualifications: How can I become a polisher?

There are no specific qualifications required to become a polisher. It takes hours of practical training to become a well-respected and trusted polisher. Many polishers will have completed an apprenticeship but completing a metalsmithing degree will also give you a foundation to become a polisher.

There are several ways to start out in the jewellery, silversmithing and allied industries. To become trained as a polisher you may choose to go straight into a job, apprenticeship or relevant course at a college, university or training centre. There are very few skill-specific qualifications available, but many courses provide an introduction to a range of creative skills. To find out more about different options and your potential route into a creative career within the goldsmithing industry click here.

What can I earn as a polisher?

As an apprentice or someone who is training you should be paid at least the National Minimum Wage for your age and this rate should increase as you get closer to completing your training. Apprentices undertaking traditional training may start out earning around £12,000 – £13,000 per year and be closer to £17,000 – £18,000 at the end of their four-year apprenticeship. Once you have completed your training your earnings will vary depending on your skill and employment status.

Polishers generally charge by the job for polishing and plating. You will benefit from having a good understanding of the construction of the piece and the materials used when costing a job.

Salaries for an employed polisher can start at around £22,000 - £25,000 per year in the first few years after training. This can rise to around £30,000 for a mid-career polisher and can reach £35,000 - £40,000 for the most experienced and skilled polisher working for a top silversmithing company.

If you are self-employed, being a polisher can be well paid if you have regular clients or constant sources of work, but it can be difficult if you only receive work on an ad hoc basis. As a polisher you are reliant on other craftspeople or clients bringing you work and will normally agree a fee per job. Rates for this will depend on your experience, the materials being polished or plated, and the complexity of the piece required by the client. No matter how you work your reputation is extremely important as the goldsmithing industry often operates on word of mouth recommendations and trust.

What industry bodies can I join?

The Goldsmiths’ Centre offer a range of membership options for people at different stages of their career. Joining a membership body or keeping up to date with industry events allows you to create a network with like-minded individuals. They might also run workshops to acquire new skills. See for example:

Meet the makers

Polishing is very underrated in the jewellery industry; you can be given a piece that is dull and lifeless and through polishing it correctly, bring it to life.

Examples of polished work

The Goldsmiths’ Company Collection includes over 8,000 pieces of antique, domestic & contemporary silver, jewellery and art medals which were made in Britain between 1350 and the present day. The Company continues to purchase, and commission pieces each year and new contemporary pieces must demonstrate innovative design combined with excellent craftsmanship. Pieces are acquired from both established craftspeople and rising stars.

Clive Burr, Richard Madeley’s Court Wine Cup, 2019 © Collection: The Worshipful Company of Goldsmiths

Clive Burr, Richard Madeley’s Court Wine Cup, 2019 © Collection: The Worshipful Company of Goldsmiths

Richard Fox, Pair of 4 Light Candelabra, 1984 © Collection: The Worshipful Company of Goldsmiths

Richard Fox, Pair of 4 Light Candelabra, 1984 © Collection: The Worshipful Company of Goldsmiths

Richard Fox, Riviera Jug, 2008 © Collection: The Worshipful Company of Goldsmiths

Richard Fox, Riviera Jug, 2008 © Collection: The Worshipful Company of Goldsmiths

Alex Brogden, Dish 1990 © Collection: The Worshipful Company of Goldsmiths

Alex Brogden, Dish 1990 © Collection: The Worshipful Company of Goldsmiths

Alex Brogden, Polyhedron Vase, 2015 © Collection: The Worshipful Company of Goldsmiths

Alex Brogden, Polyhedron Vase, 2015 © Collection: The Worshipful Company of Goldsmiths

The Goldsmiths’ Company also retains an image archive of Masterpieces created by apprentices in their final year on the Goldsmiths’ Company Apprenticeship Scheme.These pieces take around 350 hours to make and demonstrate the skills learnt throughout an apprentice’s training. A selection of these pieces, which demonstrate polishing, can be seen here:

Barney Bowes, (Asprey Ltd) 8 inch Combination Safe 2017 © Collection: The Worshipful Company of Goldsmiths

Barney Bowes, (Asprey Ltd) 8 inch Combination Safe 2017 © Collection: The Worshipful Company of Goldsmiths

Barney Bowes, (Asprey Ltd) 8 inch Combination Safe 2017 © Collection: The Worshipful Company of Goldsmiths

Barney Bowes, (Asprey Ltd) 8 inch Combination Safe 2017 © Collection: The Worshipful Company of Goldsmiths

Further information

There are many reputable sources of information relating to the jewellery, silversmithing and allied industries. Whether you are trying to find information on technical skills, processes, materials, makers or inspiration some resources relating to polishing can be found below:

The Goldsmiths’ Company Library relates specifically to gold and silversmithing, jewellery, assaying and hallmarking, precious metals, and the City of London and its guilds. The Library includes 8,000+ books and 15,000+ images, magazines, periodicals and journals, technical guides, films, special research collections, design drawings produced during the early and mid-twentieth century by British or UK-based craftspeople and subject files on a wide range of industry related topics. The Library is also responsible for the Company’s archives, which date back to the 14th century.

Polishing related books include:

- Rupert Finegold and William Seitz, Silversmithing, Wisconsin, Krause Publications, 1983

- Robert Goodden & Philip Popham, Silversmithing, London, OUP. 1971

- Brian Hill and Andrew Putland, Silversmithing. A contemporary guide to making, Ramsbury, The Crowood Press, 2014

- Frances Loyen, The Thames and Hudson manual of silversmithing, London, Thames and Hudson, 1980

- Stephen M. Goldsmith, Polishing and finishing for jewellers and silversmiths, Ramsbury, The Crowood Press, 2019